3-Axis Fiber Laser Marking of Medical Implants

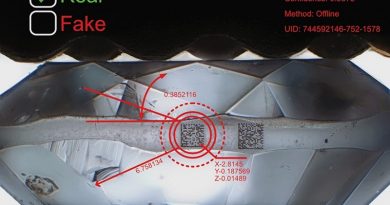

Custom Systems and Controls was asked to build a Laser Marking System to mark a wide variety of metal medical implant components, ranging in type and size with multiple marks on each part.

CSC designed a Laser Marking System with a motorized X-Y gantry, a rotation stage and multiple custom fixtures to hold the wide array of parts to be marked. The fixtures were capable of accurately holding, and if necessary, rotating multiple parts at the same time.

A custom PC application was developed that allowed the customer to store marking recipes for each part that could be recalled by a simple bar-code. Each recipe contained basic setup information such as the type of fixture to be used, whether rotation was necessary, etc.

The recipe contained the details of each step in the marking process for that specific part. This included the location of each mark on the part and the text to be marked.

System Components

- Keyence MD-F3100/5100 3-Axis Class 4 Yb:Fiber Laser Marker

- Intel i7 Fanless PC

- Bar Code Scanner

- Custom Enclosure with Laser Safety Window

Success

The flexibility provided by the software was key as it allowed for quick setup and unattended operation of a complex marking process. It also simplified the maintenance of the marking programs as the number of unique programs was kept to a minimum due to the ability to modify parameters based on the recipe database as opposed to creating a customized marking program for each unique part.

CSC was able to successfully complete the project on time and on budget. The unit has been in operation since installation with no major repairs and is still performing for the client.

For more Information: www.custom-sys.com/ www.keyence.com