MECCO Laser Marker Helps Ford Track Data

MECCO developed a revolutionary new method for safely using a laser to mark large items. This new patented technology is helping a number of companies like Ford Motor Company’s Livonia, Mich., transmission plant to integrate a safe laser marker into their existing production line.

Frank Maslar of Ford’s Advanced Manufacturing Technology Group states that “Ford has been focused on implementing traceability solutions across all of our production. Ford will utilize this laser marked data for tracking information to maintain process control to help ensure that the quality of the manufacturing of our vehicles is of the highest quality.”

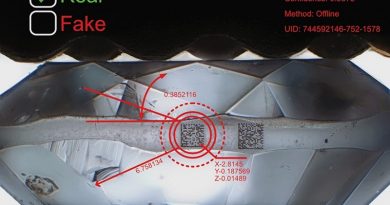

Ford has integrated the MeccoMark® 20w Fiber Laser Marking System with the Safety Seal option. These systems permanently mark critical information in both 2D Data Matrix and human readable forms on each transmission case as it enters the production line. This laser marked information will be read and verified at several predetermined points along the transmission production line.

The decision to implement this laser marking system into Ford’s assembly process was made when MECCO’s innovative design was selected based on Ford’s specific cost, product, and facility considerations. The Safety Seal’s patented design allowed for safer and more cost-effective 2D direct part marking at Ford.

These systems have met Ford’s transmission-specific marking needs, where traditional flash lamp laser markers with extensive safety guarding are cost-prohibitive. As an integrated part of the assembly process, MECCO’s Safety Seal unit requires only a small footprint to apply an easy-to-read 2D Data Matrix code during the transmission assembly process. Operating as a small, compact unit, it will easily integrate into assembly lines, and it functions with dramatically less factory floor space due to the elimination of the large safety enclosures required by other laser marking system designs.

The patented Safety Seal system does not inhibit Ford’s assembly line production like other traditional laser marking systems. MECCO’s proprietary CDRH Class 1 laser safe approved design confines the laser beam to a small, light-tight enclosure to protect against laser light exposure.

This system is ideal for Ford’s requirements for automated data creation of dates, code, and serialization, as well as other information essential for automotive part service and warranty tracking.

The patented SMARTmark® Safety Seal delivers Class 1 laser-safe integration without the need for expensive and large enclosures. The innovative design on the Safety Seal uses the part as the sixth side of the enclosure by vacuum sealing against the part, creating a light-tight, laser-safe environment.

All Safety Seals utilize a fume removal system to evacuate the marking debris in order to maintain internal cleanliness and mark quality.

Benefits

- Ideal for large parts: engine blocks, transmission cases, crank & cam shafts, vehicle frames

- Economical solution compared to large enclosures

- Reliably used in automotive production plants

System Features

- Compatible with any power level of SMARTmark Fiber and Tiburon Lasers

- Easy to integrate – Integrates with your production line to know what and when to mark

- Sliding snorkel to meet the part

- Helps with part location variation

- Ideal for large parts

- Up to 4″ circle marking area

- Fume removal system is supplied with every system – I/O triggered

- Easy-to-remove protective window for lens cleaning and maintenance

- Customizable rubber seal for part geometry and surface finish

- Laser will only fire when properly sealed to the part

For more Information: www.mecco.com