Advanced Manufacturing and Processing Enhance Custom Stamps

Advanced Manufacturing And

Processing Methods Enhance

Columbia Marking Tools’ Custom

Steel Stamp Capabilities

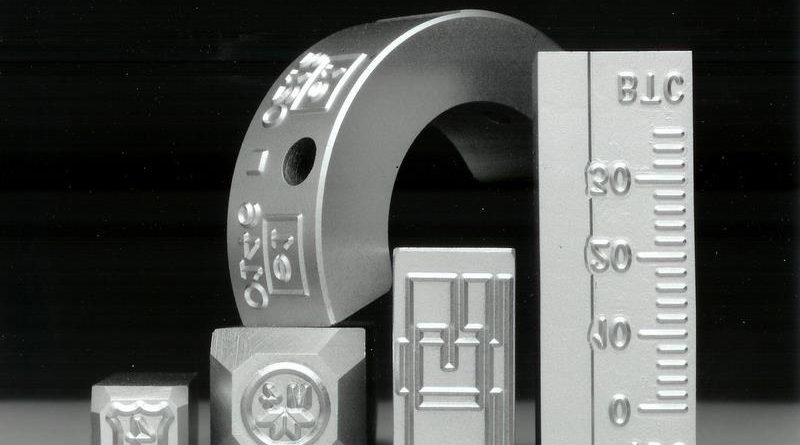

Custom stamp patterns made to size with CAD and CAM significantly reduced manufacturing and processing time.

Columbia Marking Tools is a leading designer and manufacturer of metal and plastic marking equipment including stamps, roll marking dies, roll marking and impact marking machines, fully programmable pulsed fiber diode laser, peen/scribe marking and UID/2D Square Dot® machines, numbering heads and special marking and vision inspection machines.

High-speed steel and tool steel hand stamps, press stamps, impact marking dies, and roll marking dies are a big part of Columbia’s core business. But having the ability to precisely and efficiently produce custom stamps for any logo or symbol configuration or special typeface is a capability not mastered by many stamp producers.

By implementing computer-aided-design into our manufacturing process, pattern making time has been significantly reduced. This improvement has greatly enhanced the ability to produce complex stamp configurations and reduce delivery schedules.

Andy Habedank, Columbia’s chief engineer, says, “ CAD technology was really Phase I of a product improvement program that will now includes computer- aided-manufacturing. By implementing CAD methods, we are able to duplicate or design, manufacture and deliver custom stamps in two weeks. In addition, with CAD pattern drawings we are able to better illustrate to customers where stamp wear life problems can occur and recommend slight design improvements that will reduce failures or breakage.”

Habedank adds, “The key to being a successful custom stamp maker is having the ability to cost-effectively make an accurate pattern, select the proper high-speed or tool steel material for the application, heat treat to rigid specifications, and have the toolmaking know-how and experience to produce it. We’ve made important incremental improvements with the application of CAD and CAM. By integrating those capabilities with CNC manufacturing will continue to made additional improvements.”

For more Information: www.columbiamt.com