New Telesis All-In-One UV Laser with 3D Marking

Telesis Technologies, the industry leader in Product Identification and Processing, has developed a revolutionary new design for the laser marking industry. The UV/one utilizes the most advanced technology on the market. The new lower cost design allows for a much wider range of material surfaces and materials not seen before in laser marking.

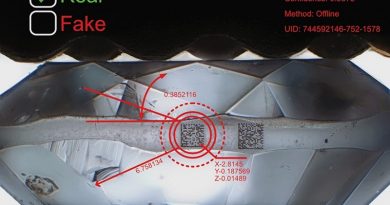

Traditionally the laser beam will travel through a flat field lens and focus the beam on the surface of the part to be marked. With the new Focalist™ technology from Telesis, the UV/one™ laser no longer requires the focusing of the beam through a flat field lens. The beam has a pure direct light allowing it to have a very large focal point. This new technology uses a proprietary focal tolerance expansion process unique to Telesis.

“The beam is so forgiving you can mark significant amounts of material without the need to move the part or laser,” said Ashot Mesropyan, President of Telesis Technologies, Inc.

Advancement in technology allows the laser and controller to be contained all within the marking head. Measuring just 7 inches X 7.5 inches X 24.4 inches (178 mm X 191 mm X 620 mm), the compact all-in-one unit can fit into even the most crowded production line. This also eliminates the possibility of the laser source delivery system becoming damaged as it travels from the controller to the marker. The only connections needed are the standard 110v power, a cable for a small control pendent, and the standard Ethernet connection that can be connected to desktop or a laptop computer.

Optics that can be adjusted or moved can move over time causing the beam to become out of alignment. The UV/one™ laser incorporates fixed optics to ensure the laser is always in focus and reliable. Our lasers are assembled at our facility in Fremont, California by a team of laser specialist who carefully and permanently align the beam for precision placement. Once set, the optics will not move eliminating the need for costly service adjustment over time.

“We don’t have moving optics inside the laser. Thus it’s more reliable and robust,” said Ashot Mesropyan.

The UV/one™ has many other advantages as well. For example:

- The UV/one™ can mark a very wide range of materials sometimes impossible to mark with other types of laser technology.

- The UV/one™ can produce a very high contrast mark with very minimal surface disruption.

- The UV/one™ can be incorporated with the Telesis iZONIT™ Technology allowing the user to visually see the part on the screen.

- The UV/one™ is capable of on the fly marking.

- All of the Telesis laser systems use the Telesis Merlin® software.

“Our idea was to come up with a system that was functional and at the same time very affordable,” Mesropyan said.

Telesis Technologies Inc. is a world leader in manufacturing standard and customized permanent parts-marking/processing equipment and systems – including a broad range of laser marking and PINSTAMP®, systems. Since 1971, Telesis has provided durable and accurate parts marking capabilities worldwide, from small shops to Fortune 100 manufacturing firms and governmental organizations. Telesis is now the most trusted brand in the parts marking industry.

Telesis solution capabilities incorporate material handling, enclosures, conveyors, encoders, part present sensors, touch screen, integrated PC as well as custom turnkey integration applications backed with full service support. With know-how gained from tens of thousands of installed marking systems globally in automotive, aerospace, medical, general machining and packaging applications.

For more Information: www.telesis.com