Why Roll Marking?

From Al Hall, Editor PARTMARKING.NEWS

Roll Marking by means of rolling dies is fast, quiet and cost-efficient

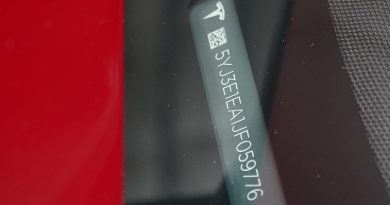

Practically every type of manufactured part requires some form of permanent identification marking. These marks may be such things as part numbers, lot numbers, QC marks, company logos, trademarks, date & shift codes, traceability marks, and even QS9000 and ISO compliance indication.

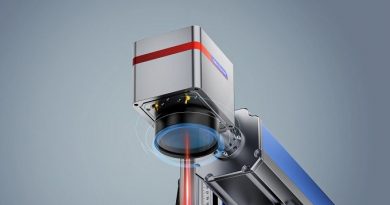

Today, the methods used to mark parts is as varied as the type of information that needs to be marked. Impact markers, laser markers, pin markers, hot stamp markers…there are many methods and different technologies to choose from. But the one method that is unquestionably the fastest, quietest, and most cost-efficient is “roll marking”. And in machine form, it is a highly durable process and provides the user with a piece of equipment that has very high re-sale value.

Long Used But Little Understood

Roll marking is certainly not a new method or is it advanced technology. Companies have been designing and building roll marking machines for over sixty years. But the process has tremendous versatility. Roll marks can be applied electrically, hydraulically, or pneumatically depending on the part to be marked and the nature of the mark itself. Mechanically, roll marking can be accomplished with a variety of methods. A round part rolls past a flat die, a round die can roll a flat part, or a round die can roll around a rounded part. Another advantageous characteristic is that, depending on the power system used, roll dies can be made to follow uneven surfaces while maintaining a uniform impression depth. A prime example is a rough cast surface.

Because a rolling die has a relatively small point of contact with the part to be marked, it uses only a fraction of the pressure that is typically required by an impact marking machine. For example, roll marking machines can mark fragile parts by reducing marking force requirements from 55 to 95%.

The Part and the Mark

For the designer and builder of roll marking machines, there are three basic factors that determine what type of machine that is best suited for an application.

1) The size, type and material make-up of the part to be marked. Is it hollow, thin-walled, solid, rigid etc?

2) The mark that is to be applied. How many characters in the mark. How many lines of characters. The size of the characters.

3) The production rate required. Pieces per hour, batch runs, manual, or fully automated, and the automation to bring parts to and from the machine.

Marking depth, or the impression depth, can range from 0.001″ to o.o15″. Typical applications are in the 0.005″ to 0.015″ range. However, some applications such as pressure tanks and truck frames, where thick paint or coatings are applied, require extra deep marks, Also, the amount of ‘raise-up’ needs to be considered. This characteristic of impression marking sometimes fools the user when estimating marking depth. Because metal is basically being displaced by the force of the roll die, the displaced metal it raises up around the outside of the marked impression. Should this ‘raise-up’ cause a part to be our-of-spec for subsequent assembly o, or further processing, roll marking can roll the ‘raise-up’ back into the part surface and still leave a visible mark.

The Marking Die

Fine grain tool steels, such as water and oil hardening and high-speed steels, are selected for the specific die application. The die blank shapes are carefully pre-machined by skilled craftsmen who engrave each character with high speed milling machines to produce accurate, geometric shapes. This is very important because the engraving produces the working edge of the die which moves the metal as it penetrates the part that is being marked. Each die is brushed to remove any burrs prior to being heat treated. After hardening to typically 559-62 Rc the hardness is checked. Then each die goies through a resizing process so the dies are accurately ground to final exact tolerances. are manufactured from various tool steels depending on the application.

Marking Die Design

Each application also determines the roll die design. The impression (mark) may require, for example, a smaller diameter roll die resulting in further reduced point contact, thus lowering the force necessary to penetrate the part surface. Sharper engraving angles can be considered to reduce marking pressures. For tough marking operations that require added character strength, wider engraving angles may be required. In recent years, Dot Style characters are produced by engraving several adjacent, pointed cones to make up each character. This style was originally produced for the nuclear energy industry where stress riser points on pressure fittings were a very important concern. Applications such as marking the length of a round bar with more than one line of characters (or very large characters) is accomplished by concave engraving of the die, allowing the mark to ‘wrap around’ the part. Roll dies can also be engraved with multiple impressions for increased tool life. The use of morticed slots allows insertion of changeable character segments (for date codes or part numbers), which can reduce overall tooling costs. Split die designs used to produce dies to mark hexagon and octagon shaped parts on two adjacent surfaces simultaneously. Roll dies can be relieved ;in one section to facilitate loading and unloading of parts or two clear projections on marking surfaces. Roll type holders are designed to hold individual character, logo, and segment dies for applications requiring frequent and/or complete impression changes.

Roll Marking Machines

The majority of roll marking machines are designed and built for the application. Many applications are similar and share basic roll marking machine designs. However, loading/unloading methods, fixturing, automation, dies and holders may vary greatly. For example, hydraulically-operated roll marking machines are relatively fast, typically producing a marked part every 1 to 10 seconds and can exert tremendous marking pressure for deep marks. Air-operated designs typically ae less expensive and produce less marking pressure than hydraulic models. High-speed electric motor powered designs can mark continuous bar stock at rates of 270 ft/min. Assuming a final part length of 2″, these high-speed machines can mark parts at phenomenal rates of up to 97,200 parts per hour.

(Many thanks to the engineers at Columbia Marking Tools for providing the information and illustrations for this article)