DataMatrix Laser Code Marking of Cast Aluminum Wheels

Innovations must offer added value, and with this in mind Heitec PTs GmbH developed the HeiDetect Wheel Robot for automatic wheel testing of cast aluminum wheels for detection of casting defects. The consistent add-on to this is the new compact HeiLaser Wheel. This system arks wheels by laser, paving the way for simple, individual traceability. DataMatrix code marking takes place directly after X-ray testing at the wheel testing facility. All steps are carried out in in-line operation with neutral cycle time. Defective wheels can be marked as such and sorted out later.

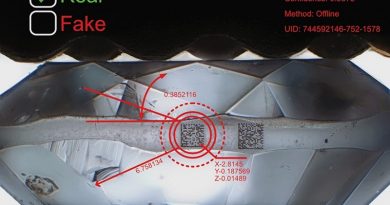

The DataMatrix code marking of a wheel with the HeiLaser Wheel takes a maximum of 17 seconds and is done simultaneously to the cycle time of the X-ray test using a 50 watt laser. The resulting DataMatrix data of individual workpieces can be clearly assigned. All settings are stored centrally, from the test parameters to DataMatrix code. Wheels can always be traced back to the raw casting condition and the corresponding X-ray images. Lasering is done from below through the conveyor system, so the wheel does not have to be moved.

Typically, the wheels are clearly marked in the early stage of the production process before further processing. The early identification at the beginning of the value chain makes it possible to clearly allocate data across all production processes and beyond.

The combination of HeiDetect Wheel Robot and HeiLaser Wheel is a compact solution can be connected directly at a wheel testing facility. With this “backpack solution”, it requires very little space and can be optimally integrated into existing production processes. With either new or already existing systems HeiLaser Wheel can be easily retrofitted.

Basic Advantages include:

- In-line marking directly after X-ray testing

- No additional time required: Marking takes place in 17 seconds parallel to cycle time

- No manual intervention due to complete arrangement of testing and marking

- Seamless traceability, as wheels are marked sustainably

- NIO wheels can also be optically visibly marked, eliminating the need for an additional Station

- Space-saving, direct integration in HeiDetect Wheel Robot

- Reliability, because all high-quality system components are from Heitec

- Easy operation, because all settings are integrated in one Software

- Maximum information density on the wheel, because even foundry information can still be unambiguously assigned

- Traceability of all data even after delivery is possible (marking in relief pocket)

- Can be retrofitted also for existing in-line wheel testing facilities

- Optimum quality assurance – thanks to integrated counter-reading of the DMC after marking

- Wheel diameters from 350-700 mm with wheel widths from 100-385 mm can be accommodated

- Maximum wheel weight can be up to 50 kg

- DataMatrix Code size is 10X10 mm

For more Information: www.heitec-pts.de