Metal Marking with a CO2 Laser

You don’t need a fiber laser to achieve great quality marks on metal. CO2 laser machines can directly mark a variety of coated metals such as anodized aluminum or powder coated stainless steel. However, bare metals reflect the wavelength of a CO2 laser, meaning direct marking typically requires a fiber laser source. Fortunately for CO2 lasers provide an excellent option. Bare metals like titanium or nickel plating can be pre-treated with a metal marking compound prior to marking with a CO2 laser.

The advantage of metal marking with a CO2 laser is that the mark is actually produced on top of the metal, without removing material, so there is no impact on the metal’s tolerance or strength. It should also be noted that coated metals, such as anodized aluminum or painted brass, do not require pre-treatment.

More time is required for marking metals with a CO2 laser, for instance, because of the need for coating or pre-treating with a metal marking agent. The laser must also be run at a low-speed, high-power configuration to allow the marking agent to adequately bond with the metal. Users sometimes find that they are able to wipe off the mark after lasering – an indication that the piece should be run again at a lower speed and higher power setting.

The pre-treatment process is simple, and while it will not actually remove any of the metal material, you will be left with a durable and permanent raised mark on your bare metal products. The heat from the CO2 laser bonds the marking agent to the bare metal, resulting in a permanent mark. Operators simply apply the marking solution (or paste) – some common products include Cermark™, Enduramark®, and LaserBond® – allow it to dry, and then perform the engraving as normal. The heat from the laser bonds the solution to the metal, resulting in a permanent black, silver, or sparkle-type mark from a CO2 laser machine.

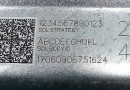

Using a metal marking spray like Cermark™, Enduramark®, and LaserBond® allows laser owners to perform all kinds of applications such as customizing jewelry and accessories, personalizing stainless steel flasks and phones, providing identification tags and barcodes, even serializing parts.

For more Information: www.epiloglaser.com