Laser Marking Surgical Instruments and Medical Tools

Permanently legible and solid laser markings on surgical instruments and medical tools.

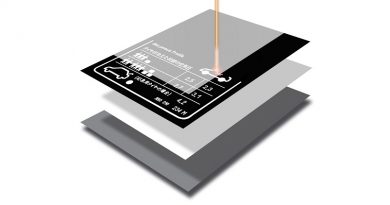

The high standard of hygiene plays an important role in medical technology. Markings that are applied by other methods, such as gluing, color printing or needle embossing and scribing, carry the risk of germs and bacteria settling in the markings.

With laser systems from Östling you meet the requirements of the hygiene standard. Durable, legible and high-contrast markings – whether plain text or codes – are possible without problems.

Unique markings for the entire life cycle of a product

A common problem with traditional laser marking is corrosion. Laser markings must not shorten the life cycle of medical products, surgical instruments and tools. Especially products made of steel or other metals must not rust in the marked area after cleaning or disinfection.

The Solution

Based on 50 years of experience in product identification and marking, Östling develops high-precision and special applications for almost all industries. Specially developed marking systems for medical technology products, such as surgical instruments, dental tools or implants make marking with plain text or codes (e.g. UDI – Code) possible without any problems – and all this in compliance with FDA and MDR standards.

With the marking software “XS – Designer” from ÖSTLING you can generate any conceivable machine-readable code. The software was specially adapted to the needs of the medical sector for compliance with FDA and MDR guidelines.

Markings on steel or other metals

By optimizing the pulse width, peak power and wavelength of laser marking systems, rust formation on metals is minimized. The inscriptions or markings of ÖSTLING laser marking systems are robust against passivation and sterilization.

All possible metals such as aluminium, copper, all types of steel, brass, titanium, nickel, chrome, magnesium, zinc, silver, gold and metals with special coatings can be marked with ÖSTLING’s laser marking systems.

When marking e.g. surgical instruments with anodized coating, the surface or the anodized coating is not damaged. The corrosion resistance as well as the thermal properties and electrical insulation are fully maintained. The markings themselves have an extremely high resistance to passivation and autoclave.

For more Information: www.ostling-markingsystems.com