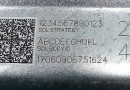

Marking Lot Numbers on Truck Cabin Doors

SIC Marking integrated their i63s scribe marker into a leading truck manufacturer’s sheet metal and welding assembly cell. A e10R control was provided and installed in the automation cabinet.

The integrated marking solution i63s is a compact yet robust design engineered for seamless integration into industrial workstations, particularly where reduced noise levels are essential. Its internal components are protected by a rugged cabinet and stainless steel bellows. Requiring minimal maintenance and no consumables, the integrated marking system i63s has very low operating costs. The flexibility of the e10R controller and the durable reliability of the i63s marking head combine to create a powerful, efficient, and easy-to-use system that is suitable for all types of industrial marking.

The i63s marking head has a marking window of 60 mm x 30mm and uses a 60 mm carbide or Diamond tip. Maximum stylus stroke is 2 mm. It weighs 7.8 kg. Dimensions are 160 mm x 170mm x 340mm.

The e10R controller is equipped with an innovative microprocessor that offers immediate start up and smooth browsing, and its comprehensive software suite allows for linear, angular, radial, and mirror image marking. An optional 3rd/4th axis circuit board can be installed to control a motorized column and/or rotary axis. Self-diagnostic and machine history functions are also included. It has a sealed membrane keyboard and 480 x 272 pixels backlit LCD color screen, providing the operator with a direct and easy-to-use interface. The controller’s dimensions are 112mm x 380mm x 222mm. It weighs 5 kg

In operation, the robot in the welding cell places the door on the welding tool. The marking is done at the same time as the welding with marking noise that does not exceed 75 dBA.

The integration of SIC Marking’s solution was accomplished without increasing the existing workstation’s cycle time. It also satisfies the customer’s environmental constraints (no noise increase generated by the marking).

The controller has been easily mounted in the control cabinet and its complete connectivity enables continuous dialogue with the PLC.